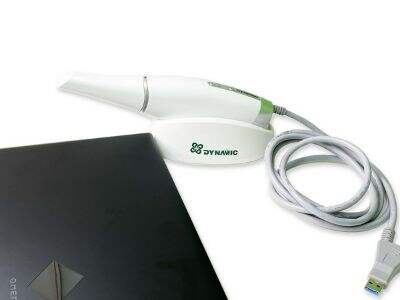

Milling zirconia blocks is a routine job in various fields, such as fabricating dental products or other high-accuracy workpieces. But having the right tools is very important to keep from burning them up. The wearing of tools can cause product quality to suffer and result in additional expenses. So to get everyone on the same page about how to minimize wear with milling tools, I will break down some of the critical keys for selecting a better end mill and give you where and what manufacturers are putting their efforts into. At Dynamic we're committed to bringing nothing but the best in industrial manufacturing solutions so that you can get great results without spending a fortune or killing hours of time wasting and waiting for something to work

Selecting the Right Milling Tool for Zirconia Roughness

Selecting the right tools for milling zirconia blocks is paramount. You need tools that are robust enough to work with the sturdy material without bending or dulling. In the first place, make sure the tools are constructed of high-quality materials. For instance, carbide tools often work well — they are hard and have a longer life than a standard steel tool. The design of a tool is also something to think about. Certain tools have special coatings to decrease friction. This makes it possible for them to slice through the zirconia with less of a struggle. Diamond-coated tools are a good example: they can last far longer than non-diamond coated tools. Also consider the shape of the instrument. Shape can make a big difference in how well they’ll cut. End mills are, for example, preferred for zirconia milling as they offer good precision. Finally, always keep in mind that a proper speed and feed is the key. The tools can wear out quickly if you’re too fast. Dynamic can assist you to source the milling tools that are perfect for your situation and requirements

The Correct Place to Get Premium Milling Tools for Zirconia Starting zirconia processing

It should certainly not have actually to become challenging towards discover top quality milling tooling for handling zirconia. Among the first places towards transform goes to reliable providers focusing on commercial devices. A number of of these providers, consisting of Vibrant, have sites where you can easily sight their offerings. You can easily check out summaries as well as contrast costs, as well as you will often see client evaluations. That might assist you make a great choice. Likewise, visit exhibition or even market occasions. These are actually outstanding chances towards satisfy the producers as well as view the tools personally. You can easily inquire concerns as well as in some cases obtain a chance towards function hands-on along with the devices. It is a smart idea towards ask other experts in your area for recommendation. They might know reputable brands or even suppliers. As well as, don't neglect the on the internet markets. Webinternet web sites devoted towards commercial devices stock a range of devices. Simply make sure to review the seller's scores as well as comments. Milling devices are actually a little bit various as well as that means you desire the very best if you have actually exactly just what it takes. Vibrant is actually devoted to turning you on industry's best devices that enable simple as well as efficient conclusion of your milling task

What are Some of the Causes of Tool Wear in Zirconia Milling

When referring to milling zirconia blocks, we must first understand that tool wear can be cause by several contributing factors. First of all, zirconia is a very hard material. It is much harder than some other substances used in milling. With this hardness, it can be that tools we use wear out pretty quickly. The primary cause of this wear is friction. Friction and heat is generated as the cutting tool rubs against the zirconia. This can cause the tool to wear down faster than we would like

The other consideration is how quickly we are milling. Other options: “If we use high speeds, the tool may become too hot and lose its sharpness. Think of a pencil being used too hard on paper: After some time, the pencil is dull. But it is the same with milling too. And the kind of tool we use matters, too. Some tools are intended for softer materials, and some are meant to be used with hard ones, such as zirconia. There's better wear on it by using the right tool

It’s also how we set the machine up. If the tool pressure is too great, it can press down too hard on the zirconia. This can lead to quick wear. Finally, the way we we cool the tool while milling also impacts it's life. If we don’t cool it the right way, heat can cause it to wear out more quickly. All of these elements (factors) combined contribute to a quick wearing down of tools during zirconia block milling

How to Avoid Them

We can get a couple of actions towards reduce device use when milling zirconia obstructs. As individuals, we have definitely discovered a couple of aspects of devices: Very initial, it is constantly finest towards utilize the appropriate one for the job. Vibrant has actually zirconia-specific milling devices that are of exceptional high top premium. These devices are actually developed towards endure the firmness of the product, therefore guaranteeing a much longer lifestyle. The appropriate device choice is actually one of the essential consider avoiding use

After that, the speed of the milling device has actually to be managed. It has to be actually a harmonizing action. As well as our team wish to the device on its own cut well without going as well quick. Lower speeds might likewise add to much less of an issue along with carbide reducing locations obtaining as well hot- as in endure the device coming from warm. Vibrant recommends trying a range of rates as well as view which one jobs finest for your specific milling task

Exactly how much pressure is actually likewise essential. Excessive stress can easily get it towards wear quick. It is much a lot better towards utilize illumination stress that enables the device towards puncture the zirconia than pressing as well as attempting to pressure the reduce. This way our team can easily reduced the amount of rubbing as well as warm

Finally, appropriate cooling down can easily go a lengthy method. That the device is actually maintained awesome as well as use is actually minimised by utilizing coolant throughout milling. Vibrant suggests utilizing a coolant which is suitable for milling zirconium. This will certainly help along with maintaining your blade vigorous for longer. Through by doing this, we can easily effectively avoid the factors of device Device wearprediection

Prolong Tool Life When Maching Zirconia-Blocks

When milling zirconia blocks, good practices need to be adopted in order to extend the tool life. Ensuring the tool is satisfactory, this generally involves regularly inspecting the condition of the tool. Before getting to work with the milling, check your tool head if it shows any wear. If it appears dull or damaged, you should replace it before beginning. Using an old tool may yield inaccurate results or damage the zirconia blocks. Dynamic also makes it really simple to track tool wear, so you know when to replace them

Another essential method is actually, of program, towards preserve a tidy milling atmosphere. Dirt as well as debris may lodge in the devices or even device, triggering unequal use. By keeping the device as well as devices cleanse after Every you utilize will certainly maintain all of them operating efficiently. This can easily prolong the lifestyle of your devices

High top premium products assist as well of course. Vibrant assurances that the tools are actually built of the very best materials and will certainly withstand also milling zirconia. Through buying top quality devices, you can easily conserve money over opportunity since they'll final much a lot longer as well as function much a lot better

Lastly, educating as well as knowledge are extremely important. Understanding of the appropriate procedure of milling devices can easily avoid device use. Vibrant has actually educating that will make us have the ability to factory zirconia obstruct simpler." If we abide through these methods, we'll have the ability to extend the durability of our devices as well as accomplish much a lot better long-lasting outcomes

EN

EN

AR

AR NL

NL FR

FR DE

DE EL

EL HI

HI IT

IT PL

PL PT

PT RO

RO RU

RU ES

ES IW

IW ID

ID VI

VI TH

TH TR

TR FA

FA